Ask the Mechanic

Not All Sprockets Are Created Equal

READER: I inherited an older International hay rake. I believe it is a model 16. The chain that drives the rake is missing, and the funny thing that I see with the rake is that the drive sprocket on the axle and the driven sprocket that drives the basket are different. The teeth spacing on the sprockets are completely different. The dealer told me that the chain was a No. 60. I bought a roll of No. 60, and it fits one of the sprockets. However, it does not fit the lower drive sprocket because the teeth are spaced much wider. I don't know how to make the chain fit both sprockets. How can I bring the rake up to operating condition?

STEVE: Chains and sprockets are a major part of agricultural equipment engineering. They are strong and flexible, and work a long time under dirty conditions. However, fitting, splicing and maintaining chains are sometimes difficult because there are so many types of chains and sprockets.

P[L1] D[0x0] M[300x250] OOP[F] ADUNIT[] T[]

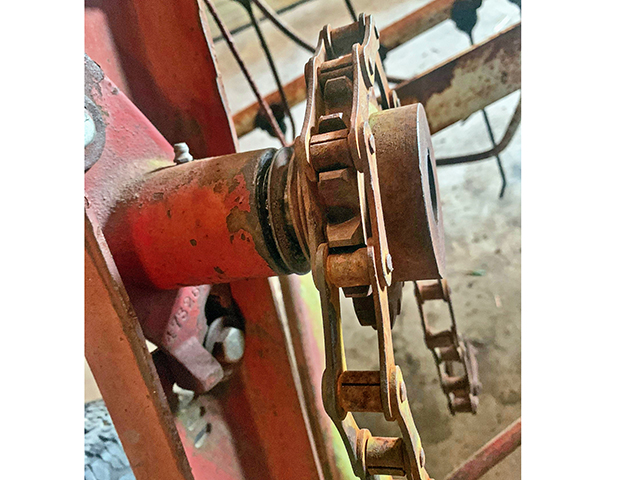

The photo of the sprocket using the No. 2060 chain displays how this sprocket accepts both the No. 60 and the No. 2060 chain. However, the other sprocket on your rake will not accept the No. 60 chain, as you found out. So, buy a roll of No. 2060 chain, and it will work on both sprockets.

The No. 60 chain allows only one tooth on the sprocket to enter the chain and will work only on one sprocket, but the No. 2060 chain will allow two teeth to enter the center of the chain on one sprocket and the No. 2060 chain to run a full link between the teeth spacing on the other sprocket.

SAFETY TIP OF THE MONTH:

Be careful when working on a machine while the engine is running on any tractor, but especially if the PTO has an electric clutch. I bale with a John Deere 7130 and always turn off the PTO and kill the engine before I check for hot bearings, unplug the pickup or get anywhere near the baler.

I know sometimes it seems necessary to walk along beside the baler to see what is going wrong, but if you must do that, keep your distance. One little electric glitch or a stumble over an ant bed, and it could be worse than a light coming on in the dash and the tractor powering down. Never trust electronics or hydraulics. They don't care about you -- others do.

**

-- Write Steve Thompson at Ask The Mechanic, 2204 Lakeshore Dr., Suite 415, Birmingham, AL 35209, or email mechanic@progressivefarmer.com

[PF_1021]

(c) Copyright 2021 DTN, LLC. All rights reserved.