Ask The Mechanic

Crimper Roll Chain Problems

READER: I am having a problem with the smaller chain that drives the crimper rolls on my New Holland Haybine 488 mower-conditioner. The machine does a great job of conditioning my hay crop, but keeping the top chain on (I lose it) is a problem. The idler for the chain is adjustable, but if I take out a link to make it adjust down on the chain, it is too short. And, if I add a half link, it is too loose. What can I do about this problem? I have lost three chains recently. The amazing thing is that the cutter runs the same without the chain, so I never know when the chain is gone.

STEVE: The problem you are having is not that uncommon when using a chain for delivery of power. When no chain idler is used, very little adjustment is provided. However, there are a couple of things you can do to eliminate your chain from "flying," caused by the chain being loose and the load constantly increasing and decreasing. By the way, I'll have to admit, when running one of these machines, I have gone a whole day without knowing the chain was gone. With the small chain gone, the roller mesh design on this machine allows one roller to drive the other roller. This is not an ideal thing, because the rubber rolls are in contact with each other all the time. When timed correctly, the rolls should never touch.

P[L1] D[0x0] M[300x250] OOP[F] ADUNIT[] T[]

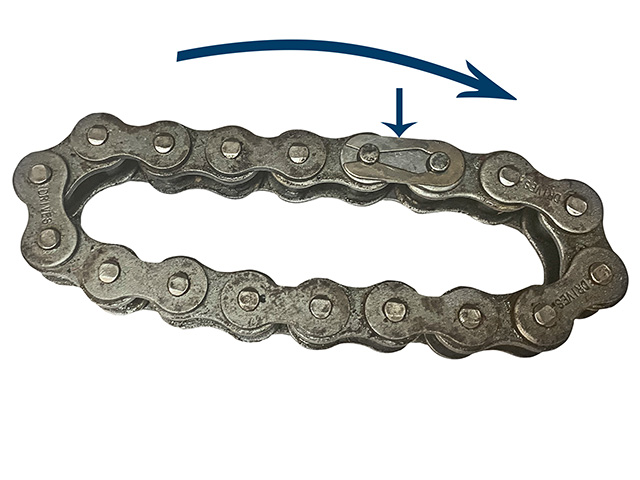

So, here is what you can do to help with the problem. First, try installing a new chain, and see how it fits. This will allow for sprocket wear. With the use of half links, you should be able to get the chain in "range" for the idler to adjust. There is one more thing you need to do that could solve your problem: When you install the master link, make sure the clip is installed so the closed end is placed in the direction of travel. In an application where it is very difficult to keep the chain tight, if the open end is leading, it is much more likely to flip off the chain.

READER: I have a John Deere 5510 tractor with a 541 loader. It has been a great tractor, but the loader now will leak down slowly. The remotes on the tractor operate the loader through a joystick. I see absolutely no oil leaking out of the cylinders or the couplers. Can you help me find the leak?

STEVE: The cylinders can leak internally and never show any sign of a leak. The oil simply passes by the seal inside the cylinder because of the pressure created by the weight of the loader when it is off the ground. It leaks faster when the oil is hot, because hot oil is thinner and sneaks by the seal easier. In order to find the leak without any tools or gauges, raise the loader and remove the hoses from your remotes. If the hose tips of the loader hoses do not leak, and the loader leaks down, the cylinder(s) are leaking internally, allowing the loader to drop. A good hydraulic cylinder repair business or your John Deere dealer can check and repair the cylinders.

SAFETY TIP OF THE MONTH:

I guess I'm a "softy" when it comes to pets. My dog Mozzie is just like your dog -- always hanging out, meaning no harm but often in the way. When feeding round bales, be sure and watch out for your dog. They have a passion for mice that have moved to your farm and are calling your round bales home. When grabbing a bale to feed, be careful that your hay fork only stabs the hay and not your valued pet, simply having fun doing the "dog thing." When dogs see a mouse, they can move very, very quickly -- even on a cold winter day.

[PF_0920]

(c) Copyright 2020 DTN, LLC. All rights reserved.